Showroom

If you need an Automatic Chapati Making Machine, then this product is definitely for you. All its operations are automated, just add the starting material/flour in it. The machine features robust design and lightweight structure.

Industrial, automatic puri making machines are manufactured by us using food-grade stainless steel and other qualitative material. It is a low noise operation and is integrated with top-grade components which increases its durability over longer continuous use.

Papad Dryer Machine is very important for making papad in perfect quality. The entire drying process is fully automatic which prevents the papads from getting deformed or burnt-out due to excessive heat. The temperature is uniform and ideal to get top grade papads.

Dough (Flour) Kneading Machine are integrated with a stainless steel drum and a motor that can be of single phase or three phase. The outer body of the machine is made from SS and cast iron, which ensure its durability.

We manufacture two models of extruder machines that can be selected on the specific parameters of screw length, screw diameter, screw speed, installed electric power and hopper size. Further, its maximum output is dependent on the profile type viz HDPE Pipe or PVC.

We are offering two version of Appalam making machines viz semi-automatic and fully-automatic. Both these require less maintenance and every part / component which comes in contact with dough is made using food grade stainless steel.

From electrical control panel to hot air generator, a host of papad making machine accessories are being manufactured by us. These are produced in standard specifications, making them compatible with all brands and models of heavy duty machinery.

Offered range of Food Processing Machines is reckoned for its contamination free processing method and low operating cost. This array of machines is used for mixing of flour, for dehydrating papad and for producing corn to suit variegated production needs of different segments of food processing industry.

Chorafali Making Machines are used for producing a distinctive type of Gujarati snack which is consumed as healthy. Driven by single phase motor, this range of machines has consistent production capacity. These systems use ingredients like gram flour and split urad lentil flour as raw materials to produce chorafali.

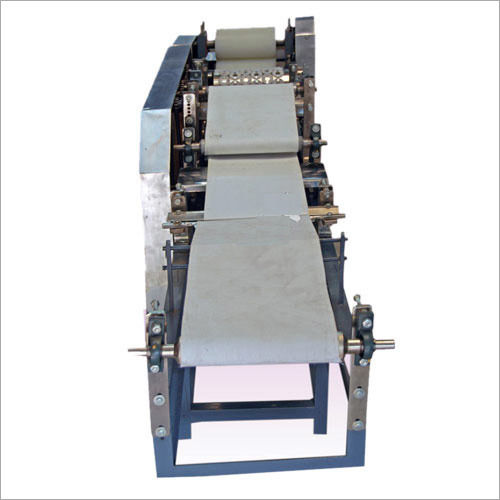

Roll Sheet Making Machines are well known for their low production cost, consistent functioning and stable performance. Entire body and contact components of these machines are made of 304 grade stainless steel to promote the concept of hygienic processing technique.

Food Extruders are considered as integral parts of snack production units where dough preparation is an important step. Made of 304 grade stainless steel, this range of machines is appreciated for its long working life, ergonomic appearance and low operating cost.

This specially engineers inline mixer is made using best material, wherein 316L stainless steel is used to manufacture its contacts parts. It is generally available in single stage rotor configuration and we can offer customization support as well.

If you need an Automatic Chapati Making Machine, then this product is definitely for you. All its operations are automated, just add the starting material / flour in it. The machine features robust design and lightweight structure.

We fabricate high speed roll making machine which has higher output rate in this category. All its contact parts are fabricated using best grades of stainless steel, which ensures its durability. Its spare parts are easily available.

Unique enclosed construction of masala mill ensures less noise and disallows dust to degrade the equipment and process. Its components, which come in contact with the dough, are manufactured using food grade material.

Roller based Pani Puri Making Machines are well known for their large production capacity, contamination free operating method and low operating cost. Minimal wastage of raw materials and smooth functioning are some of the remarkable aspects of these equipments.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free